Hot Gules Sticks Automation Packaging Line

HP-6003VDB+Auto Counting/Loading Line(Hot glue stick)

Solid Gules Sticks Automation Packaging Line

HOPAK introduces Taiwan Exclusively Hot Gules Sticks Automation Packaging Line, such connected with production line and integrated with counting, loading and packaging all at once which solves inefficiency and high mistake rate issue by manual counting. Exclusive purpose but still flexible adjustment range, this line is capable to pack Dia 7-12mm, 150-300mm length glue sticks and to be apply for 8 lanes production line connection and counting number is variable base on (8X+7Y) equation. Besides standard pillow bag packaging can do box loading mode which only counting and pass through the pack area for carton.

HOPAK unique developing hot glue stick packaging line has been sold to the Taiwan leading brand and TOP3 maker in Malaysia. HOPAK with refined machine developing and manufacture ability cooperate with senior consultant to come out the latest hot glue sticks fully automatic packaging line such not only the NO.1 in Taiwan but the machine quality is certified by international level. Based on different sticks length and loading numbers the loading plate can be adjust almost (90%) without tools. (Considering to plate strength and durable partial adjustment require sample tools)

Features

- Fully/semi automation design, customized design based on client’s need and space

- Safety covers, machine stop when opened cover

- Human interface touch screen with 50setes of memory and work resume.

- All product contact area with SUS304 (allowed to provide Material Certificate)

- Pusher material as POM (Approved by SGS for FDA standard.)

- Apply with food degree Mobil lubrication.(Option)

- For diameter 7-12mm glue stick and for 150-300mm length glue stick

- Capable to 8 lanes production line connection and counting number is variable base on (8X+7Y) equation.

- machine apply over 7units of servo drivers

- 50sets of recipe which makes the machine ideal for flexible packaging operations.

- best processing speed for 1 lane rejection up to 150 times/minutes but suggest speed 120 times/minute, without rejection can up to 200times/minute and 300times/minute line velocity for both situations.

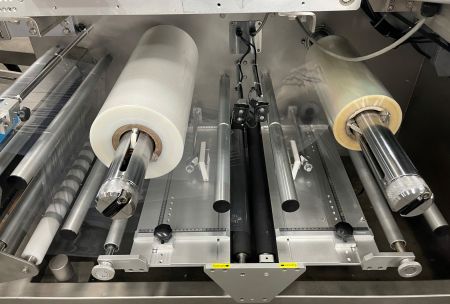

- Auto Splicer: Twin self-centering reel with auto splicing function, no film detected and auto joint new reel which keep the production non-stop.

- Perforation Holes: Attached multiple needle rings on film driving shaft which creates tiny holes on film to helps the air gets out and easily stacking for 2nd packaging.

- Anti-Misscut No Gap No Seal: High sensibility sensor gate monitor product feeding gap before sealing station, if the gap between product is incorrect will skip cutting till the gap retain correct, can only apply on transparent film or printing film but sealing part is transparent.

- Auto Splicer: Twin self-centering reel with auto splicing function, no film detected and auto joint new reel which keep the production non-stop.

- Perforation Holes: Attached multiple needle rings on film driving shaft which creates tiny holes on film to helps the air gets out and easily stacking for 2nd packaging.

- Anti-Misscut No Gap No Seal: High sensibility sensor gate monitor product feeding gap before sealing station, if the gap between product is incorrect will skip cutting till the gap retain correct, can only apply on transparent film or printing film but sealing part is transparent.

- There Layer Loading Unit: There stage loading unit: link up/ collecting / lading; lading unit can be assigned makes wider packaging flexibility

- Quick-Release Pusher: No tool required to switch pusher plate for different package size.

- Air Pressure Monitor :Smart air pressure detective system to monitor the air press and stop machine when abnormal pressure to protect machine.

- Nearly Zero Tool, Fast Adjustment:Based on different sticks length and loading numbers the loading plate can be adjust almost (90%) without tools. (Considering to plate strength and durable partial adjustment require sample tools)

- Networking: Machine computer linked with central control room for on time monitor production.

- Fast Changeover: Pusher: without tool fast-release design able to pack different height package Zero Tool adjustment: most adjust plate is adjusted without tools Over 80% belt is fast-release belt for easy maintaining.

- User Friendly, Maintain Easily :Human interface and servo motor control system with 50sets of recipe, function monitor and error alert allows operation easily, over 80% adjust part can be done without tools.

Specification

| Model | HP-6003VDB+Auto Counting/Loading Line(Hot glue stick) |

| Pack Style | Pillow bag |

| Film Material | Laminated heat sealable, BOPP, co-extrusion LLDPE (20-60mu) printed or plain. |

| Bag length | 200-500mm |

| Pack Range | For diameter 7-12mm glue stick and for 150-300mm length glue stick Capable to 8 lanes production line connection and counting number is variable base on (8X+7Y) equation. |

| Power | 3phase 415V 50HZ 15A (customized possible) |

| Film width | 580mm max |

- Pack line

- Air Pressure Monitor

- Box Motion (Gusset Device)

- Perforation Holes

- Auto Splicer

- Quick-Release Pusher

- Feeding, loading material missing detection

- There Layer Loading Unit

- Anti-Misscut No Gap No Seal

- Videos

Hot Gules Sticks Automation Packaging Line | Comprehensive Guide to Advanced Packaging Machines for Frozen and Fresh Foods

Based in Taiwan since 1992, HOPAK MACHINERY CO., LTD. specializes in advanced packaging solutions, offering Hot Gules Sticks Automation Packaging Line, cutting-edge, high-speed horizontal flow wrappers and Industry 4.0 automated packaging systems tailored for a variety of sectors including food, medical and plastics. Our commitment to innovation and quality ensures optimal packaging efficiency and durability for global business buyers seeking reliable and sophisticated packaging technologies.

At Hopak Machinery, we are a leading manufacturer of innovative packaging solutions, specializing in the development of high-speed horizontal flow wrappers and Industry 4.0 automated packaging systems. Our products serve a wide range of industries including food, medical, fresh produce, frozen food, plastic products, bakery and chocolate packaging. With a focus on integrating advanced technology to improve efficiency, safety and quality, we strive to meet the global demand for reliable, state-of-the-art packaging systems. Our commitment to excellence ensures that we provide our customers with the tools they need to succeed in a competitive marketplace.

Hopak Machinery has been offering customers bulk packaging systems, both with advanced food safety packaging technologies and 32 years of experience, Hopak Machinery ensures each customer's demands are met.